Overview of the Current Situation of Domestic Electronic Glass Enterprises

Publisher:Administrators Date:2024-03-06

Electronic glass, usually referring to ultra-thin float glass with a thickness of 0.1-2mm, is a high-tech product widely used in the fields of electronics, microelectronics, and optoelectronics. It is mainly used to make integrated circuits and glass materials with functional components such as optoelectronics, thermoelectric, acousto-optic, and magneto-optical. The chemical composition of this ultra-thin float glass is mainly composed of oxides such as silica and alumina, with silica sand, soda ash, and dolomite as the main raw materials. The manufacturing of ultra-thin glass has strict requirements in both raw materials and production processes. The thinner the thickness of electronic glass, the higher its technical requirements, the more complex the process, and the greater the production difficulty.

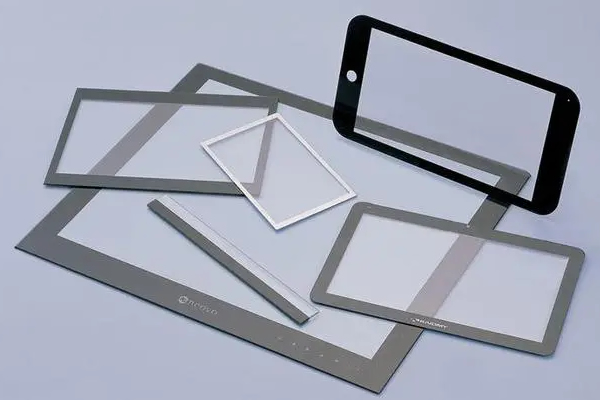

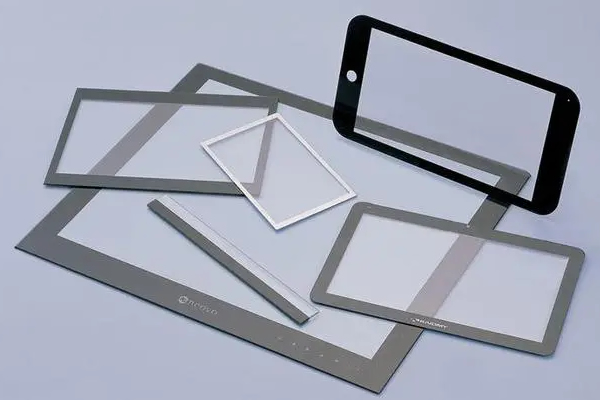

Electronic glass can be mainly divided into display glass substrate and cover glass. Display glass substrate is an important component of display panels (mainly TFT-LCD and OLED) in electronic devices such as mobile phones and televisions, which has a direct and significant impact on the performance of the panels; The cover glass is located above the display panel, providing support and protection, and ensuring that it can still maintain good display performance in the event of impact or scratches.

The upstream of the electronic glass industry's industrial chain includes raw materials such as quartz sand, soda ash, alumina, natural gas, petroleum coke, and production equipment such as kilns; The midstream is the production and manufacturing of electronic glass, including cover glass raw materials and display glass substrates; Downstream are the processing and manufacturing of window protective glass, as well as the production of display panels. Electronic glass continues to extend with the rapid development of the electronics industry. The different application scenarios determine the different requirements for the production process and performance of display glass substrates and cover glass, thus forming two industrial chains with different directions. With the advancement of glass manufacturing technology and the increasing demand for high-tech materials in downstream applications, electronic glass with excellent characteristics is gradually being applied in new directions such as automobiles, smart wearable devices, and smart homes.

Mobile: 13652371020 (Liu Sheng)

Mobile: 13652371020 (Liu Sheng) Phone: 0752-3796960

Phone: 0752-3796960 Fax: 0752-3796960

Fax: 0752-3796960 Email: wdxjk@sina.com

Email: wdxjk@sina.com Website: www.pazuan.top

Website: www.pazuan.top Company address: Room 101, Building C, Chuangxinghong Industrial Park, No. 456, Sightseeing Road, Jutang Community, Fucheng Street, Longhua District, Shenzhen

Company address: Room 101, Building C, Chuangxinghong Industrial Park, No. 456, Sightseeing Road, Jutang Community, Fucheng Street, Longhua District, Shenzhen Production address: Shentongxin Precision Machinery Co., Ltd., Kangtai Road, Lianfa Avenue, Zhongkai High tech Zone, Huizhou City

Production address: Shentongxin Precision Machinery Co., Ltd., Kangtai Road, Lianfa Avenue, Zhongkai High tech Zone, Huizhou City

Your location:

Your location:

Website

Website